Production arrows

This is only word to word translation. On the Internet there are many procedures for making arrows. On this page, bring photo-instructions, as I do. I tried making something more efficient, because the arrows are consumables, and every minute spared comes in handy. If you are going to produce a greater amount of arrows, it pays to fabricate some preparations to facilitate bonding squadrons.

We start the notch on the string. Must be cut out perpendicular to the growth rings of wood. Groove width corresponds stacked cutting a slice of the iron. I use 3 slices combined to create a 3 mm slot.

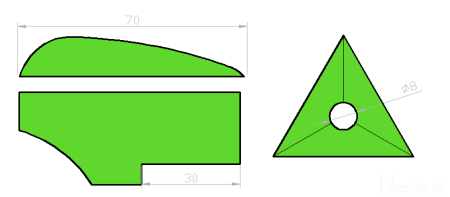

Vyhotovíme as a master template: PDF , JPG , DXF , DWG .

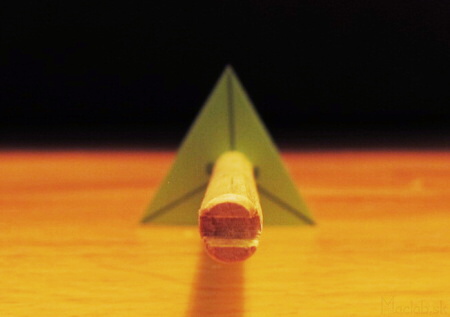

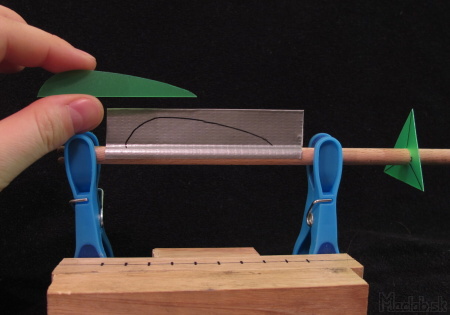

On a wooden mallet slid triangle. Turn it so that the sides of the triangle parallel to the notch on the string. From now on, do not move a triangle. Just make sure it is one of its sides parallel to the ground and have no need to worry about the correct orientation squadrons. Triangle vertices are located in letiek angular spacing of 120 °.

Plastic squadron

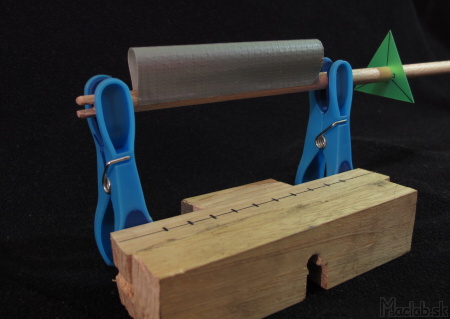

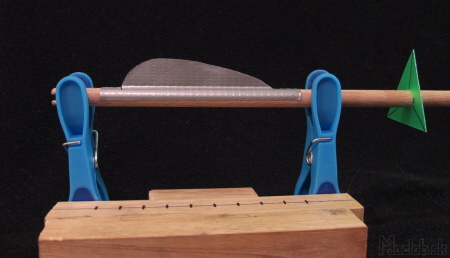

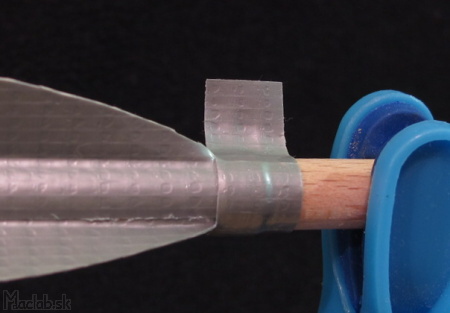

Arrow upneme into an impromptu gluing feathers. On the right arrow shot Annex industrial tape (duc-tape). The tape is pressed with your fingers, which create a surface fleet. At this stage we can give squadrons and rotation.

Scheme L-shaped indentation nazačíme a squadron from the end of the arrow.

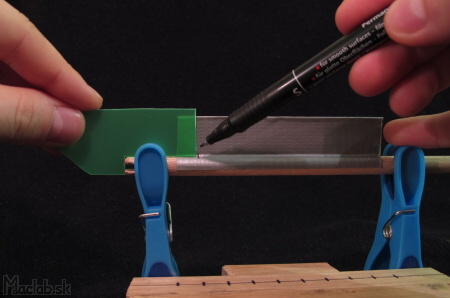

From marks on the tape Traces template squadron.

Copied and neck shape.

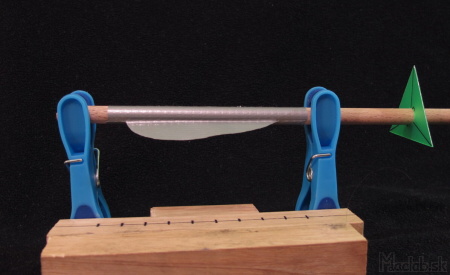

Arrow rotated so as to turn one side of the triangle parallel to the ground and continue to produce the next flight.For illustration I have photographed production of one single flight. However, it is more efficient to stick tape on all 3 directions and to eventually copied and cut out the shape.

Align the excess tape with a razor blade about half an inch from the edges squadrons. These cut off points overlap a still centimeter tape to squadrons in shooting nezadŕhali.

If a shooter has a number of arrows, not so often go to the target.

Natural feathers

Improvised splicer can also be used for bonding natural feathers. Perfect binder holding the feather in the correct position when the adhesive dries. Templates in turn use the correct orientation and offset, as was already described above.

Natural feathers are not perfectly straight, but in terms of rotation can be clockwise or counter-clockwise. On one arrow must choose only feathers with the same direction of rotation.

Feather split in half lengthwise. Then splicing the pre-planned size.

Feather gripped between two flat plates. It easier to handle afterwards. I used a broken fence.

Arrow primed with glue and attach to it a feather. After the glue dries, stick it in the same way the other directions.

Shape Opal squadron notches or to some streamlining. I left it in the style of primitive technology, only roughly trimmed with a knife. This is how I like it more. Grip cord strengthens attachment feathers on an arrow and zhladzuje transition between a feather and wood. Grip the end of the arrow on the bowstring notch reinforces that when shooting nerozštiepil.

Where to continue?

Wooden Bow - The production of wooden bow

PVC bow - bow manufacture of PVC pipe

Ballistic gel - Ballistic tests wooden bow and arrow

Strength bow - Measurement of bow and arrow speed flying